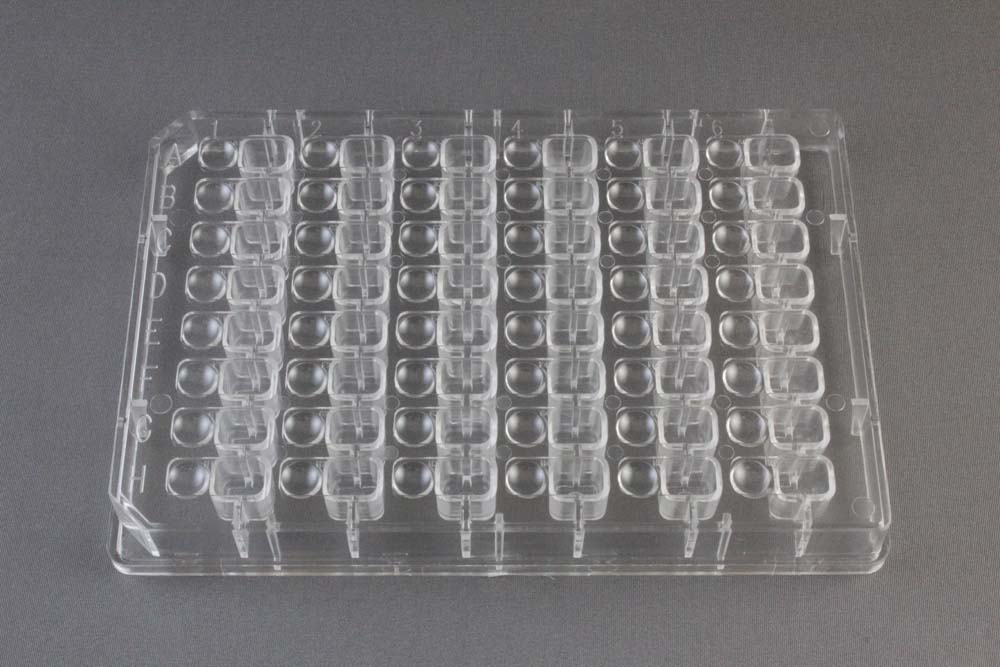

Products > Crystallization Plates, Hardware & Accessories > 48 Well Crystallization Plates > MRC Maxi 48-Well Crystallization Plate (Swissci)

MRC Maxi 48-Well Crystallization Plate (Swissci)

Applications

- Sitting drop crystallization

Features

- One drop per reservoir

- SBS format

- 48 well plate

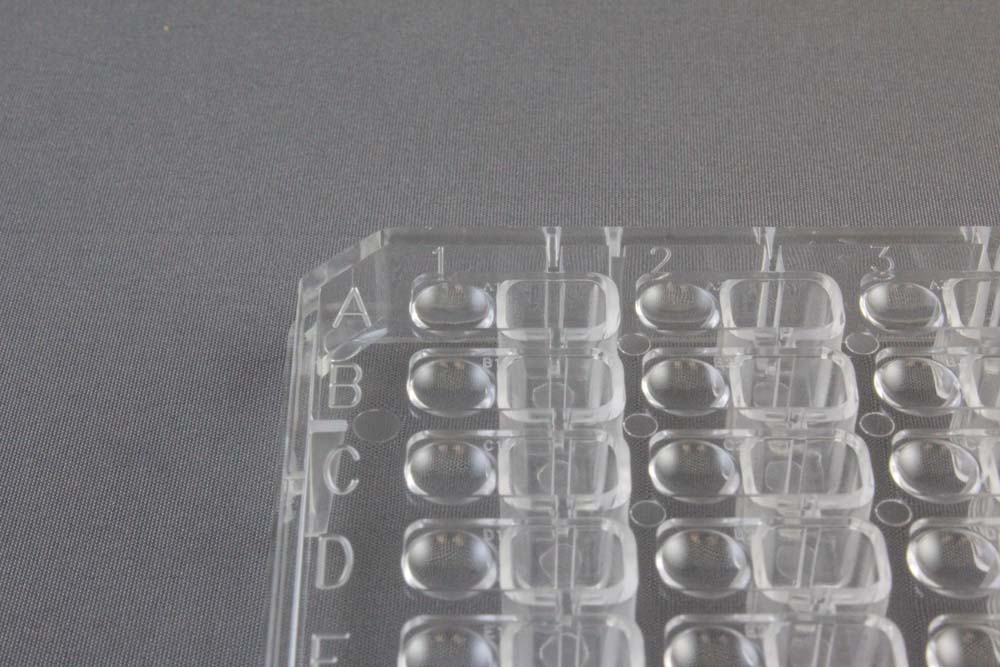

- 9 mm standard distance between wells

- Drop volume: Up to 10 µl

- Reservoir volume: 50 to 200 µl

- Micro-numbering alongside drop volumes

- Rigid plate structure

- Wide partition walls between wells improve sealing

- Developed in conjunction with the MRC Laboratory of Molecular Biology in Cambridge, United Kingdom

- UV compatible (UVP)

Description

MRC Maxi 48-Well Crystallization Plate for Automated Optimization

The MRC Maxi optimization plate is a breakthrough for macromolecular crystallization presented in a 48 well format. Offering easy to automate crystallization optimization with large sitting-drops, the new MRC Maxi Crystallization plate is the perfect solution. Manufactured by Swissci AG, the plate offers an SBS format while providing 48 wells. MRC Maxi is intended for large drops and is compatible both with standard robotic systems as well as manual pipetting.

The plate was developed at the MRC Laboratory of Molecular Biology (Cambridge, UK) in collaboration with Jan Löwe and Fabrice Gorrec. It is a result of many years of experience in successful robotic high-throughput crystallization and complements the original MRC crystallization plate, which is intended for smaller drop volumes and higher throughput during screening.

Drop volumes of up to 10 µl are possible. The 9 mm standard distance between wells is preserved, enabling the use of multi-channel manual pipettes and robotic liquid handlers, making MRC Maxi one of the most automation-friendly optimization plates on the market.

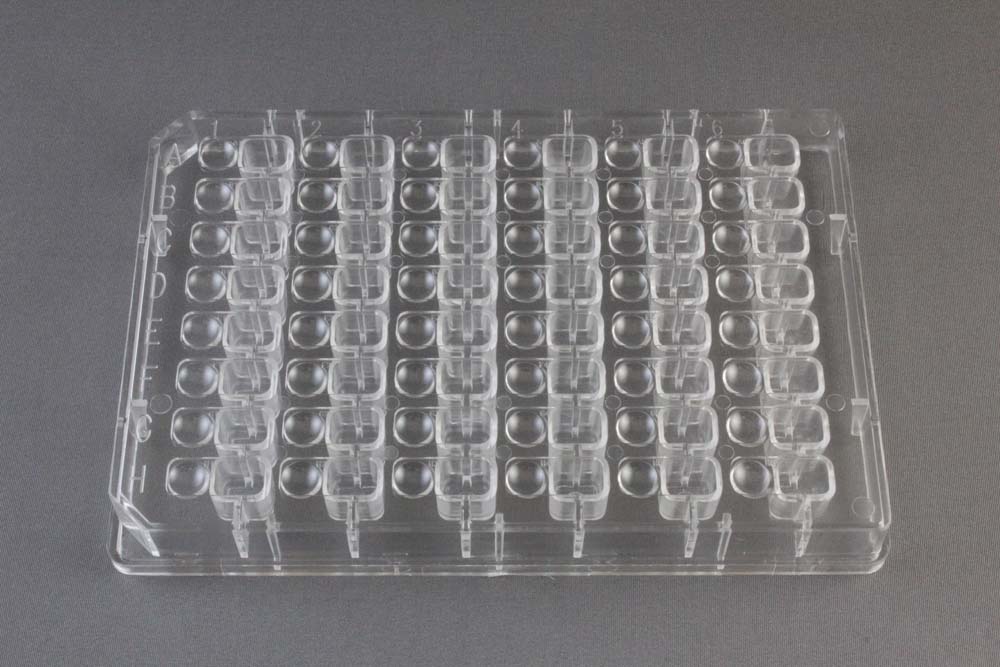

MRC Maxi is covered by global intellectual property and design registration as are the Swissci AG MRC 2 lens 96 well plates. Several breakthrough features of the original MRC plate have been maintained. Wells are labeled individually. Drops are raised for easy access during crystal retrieval. MRC Maxi uses the same proprietary polymer specially selected for the purpose of UV light visualization and the material used keeps through-plastic evaporation to a minimum. Well shapes are spherical but shallow. The

MRC Maxi Crystallization plate offers unique properties that make it the ideal choice for microliter-sized optimization experiments and is made from UV compatible UVP.

The advantages of the MRC Maxi Crystallization plate – in brief

Easy Crystal Retrieval

• Raised wide wells make the crystal mounting especially easy.

Easy Viewing

• The wells are wide conical.

• Each well has a micro lens for perfect illumination.

• Micro numbering readable under the microscope for each well.

• The optically superior polymer (UVP) is UV transmissible.

Better Sealing

• Wide partition walls between the wells give plenty of area for good sealing with tape.

Very Rigid, Automation-Friendly Plate Design

• The UVP polymer reduces through-plastic evaporation to a minimum.

SBS Standard

• The plates are designed to the SBS standard and are compatible with all common holders.

• 9 mm distance from well-to-well within columns, 18 mm distance within rows.

Unique Polymer (UVP)

• Ultra-low sample binding.

• No static charging.

Recommended Volumes

• Volumes validated for MRC Maxi are up to 10 µl of sample drop and 200 µl of the crystallization reagent.

应用

坐滴结晶

特征

每个水库一滴

SBS格式

48孔板

孔之间的标准距离为 9 mm

液滴体积:高达 10 µl

水库体积:50 至 200 µl

与液滴体积一起进行微编号

刚性板结构

井之间的宽隔墙提高了密封性

与英国剑桥 MRC 分子生物学实验室联合开发

紫外线兼容 (UVP)

描述

用于自动优化的 MRC Maxi 48 孔结晶板

MRC Maxi 优化板是 48 孔形式的大分子结晶的突破。新的 MRC Maxi 结晶板提供易于自动化的大滴落结晶优化,是完美的解决方案。该板由 Swissci AG 制造,提供 SBS 格式,同时提供 48 个孔。 MRC Maxi 适用于大液滴,兼容标准机器人系统和手动移液。

该板是在 MRC 分子生物学实验室(英国剑桥)与 Jan Löwe 和 Fabrice Gorrec 合作开发的。它是在成功的机器人高通量结晶方面多年经验的结晶,是对原始 MRC 结晶板的补充,后者旨在在筛选过程中实现更小的液滴体积和更高的通量。

液滴体积可达 10 µl。孔之间 9 毫米的标准距离得以保留,从而能够使用多通道手动移液器和机器人液体处理器,使 MRC Maxi 成为市场上最适合自动化的优化板之一。

MRC Maxi 受全球知识产权和设计注册保护,Swissci AG MRC 2 透镜 96 孔板也是如此。保留了原始 MRC 板的几个突破性特征。孔单独标记。水滴被升高,以便在取回水晶时轻松取用。 MRC Maxi 使用相同的专有聚合物,专为紫外光可视化而选择,并且所使用的材料可将穿透塑料蒸发降至最低。井的形状是球形但较浅。这

MRC Maxi 结晶板具有独特的特性,使其成为微升优化实验的理想选择,并由与紫外线兼容的 UVP 制成。

MRC Maxi 结晶板的优点 – 简述

轻松取回水晶

• 凸起的宽孔使晶体安装特别容易。

轻松查看

• 井是宽锥形的。

• 每个孔都有一个微型透镜,可提供完美的照明。

• 每个孔在显微镜下可读的微编号。

• 光学优异的聚合物 (UVP) 可透过紫外线。

更好的密封

• 孔之间的宽隔墙为用胶带良好密封提供了足够的空间。

非常刚性、自动化友好的板设计

• UVP 聚合物将贯穿塑料的蒸发降至最低。

SBS标准

• 印版按照SBS 标准设计并与所有常见的支架兼容。

• 列内孔与孔之间的距离为 9 毫米,行内为 18 毫米。

独特聚合物 (UVP)

• 超低样品结合。

• 无静电。

推荐卷

• 针对MRC Maxi 验证的体积高达10 µl 样品滴和200 µl 结晶试剂。

HR3-179/HR3-180 MRC Maxi 48-Well Crystallization Plate

Click to Zoom In

CAT NO

HR3-179

NAME

DESCRIPTION

10 plate case

PRICE

$96.00

cart quote

CAT NO

HR3-180

NAME

DESCRIPTION

40 plate case

PRICE

$375.00

cart quote

Support Material(s)

MRC Maxi 48-Well Plate Drawing

MRC Maxi 48-Well Plate DrawingRelated Item(S)

- ClearSeal Film™ and Applicator

- Crystal Clear Sealing Tape

- Crystal Clear Sealing Film